To ensure high standards of quality and reliability, our products go through a multistage testing procedure before passed fit for dispatch. The standardized testing procedure is carried out by trained personnel using up to date computerized testing equipment and software.

We adhere to and maintain the international testing and performance standards of our products and are a member of the FIA. Our world class service and high standards of quality control can also be tailored to your specific requirements. In the testing process every cable is tested and cross-checked individually.

Take Singlemode fibre optic terminations for example:

Every termination is inspected and tested, labelled with a serial number which matches up to a database logging the Insertion Loss & Return Loss results at 1310nm and 1550nm. Normal production complies with Telecordia GR***. More stringent performance can be achieved if required (IL 0.1dB typical, 0.2dB max with RL > neg. 65dB)

Optical test results sheet:

[su_highlight]Individual breakout terminations tested and results checked against set standards.[/su_highlight]

[su_highlight]Individual breakout terminations tested and results checked against set standards.[/su_highlight]

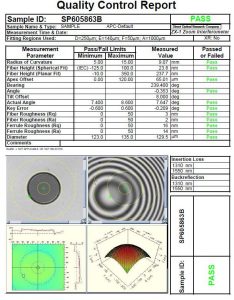

Interferometer Testing with Sample Quality Control Report:

Polishing procedures are determined using in-house Interferometry data for optimum optical performance.

We can provide end-face geometry results for customers’ own cables if requested.